Building vs Buying a Home: Which Option Saves You More Mo...

Comparing building costs between new construction and existing homes in 2025 shows significant di...

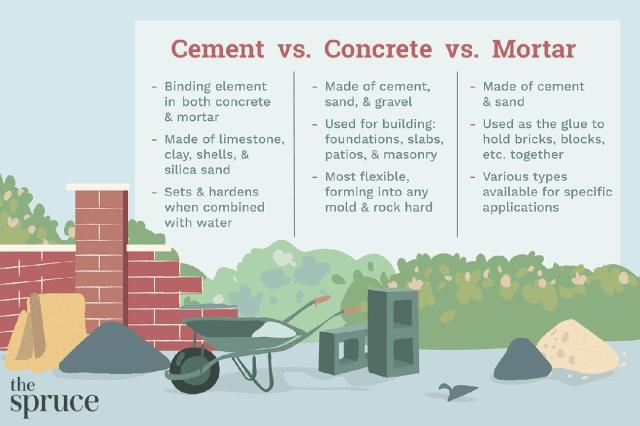

Concrete and cement rank among the most misunderstood terms in construction and home improvement. Most people use these words interchangeably, but they describe two completely different materials with distinct compositions and uses. Cement is actually just one ingredient in concrete, mixed with water, sand, and stone aggregates to create the final product. This distinction matters more than you might think, especially when planning slab installations or structural projects. Cement alone can't handle the structural demands of construction work, while concrete creates surfaces strong enough to support significant weight and resist environmental stress. Understanding this difference helps you avoid expensive mistakes, whether you're tackling a DIY project or working with contractors. Not every material works for every application, so let's discuss how concrete and cement compare to help you choose the right option for your specific project needs.

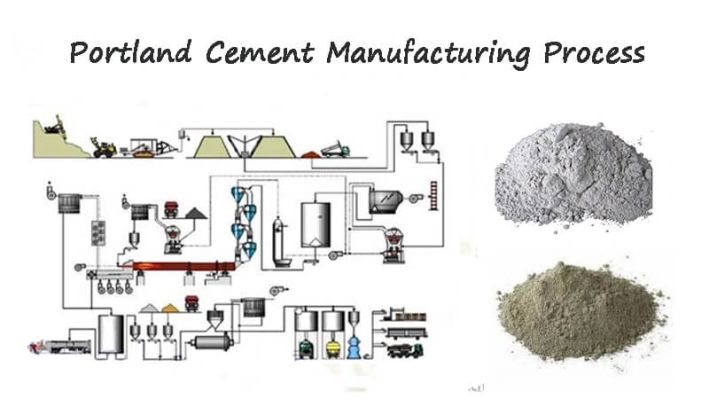

Portland cement dominates modern construction as the most common cement type available. When mixed with water, this powder creates a strong adhesive paste that hardens over time. The name comes from Joseph Aspdin, who thought the cured material looked similar to limestone from the Isle of Portland in England.

Cement works as the crucial binding element in concrete and mortar rather than functioning as a standalone material. Think of it as the foundation ingredient that makes these stronger building materials possible.

Portland cement contains four primary raw materials:

These materials combine in specific proportions to create cement's binding properties. The exact ratios vary slightly between manufacturers and intended uses, but the core ingredients remain consistent across most cement types.

Cement production follows a precise 5-step process:

The extreme heating temperatures cause chemical changes that give cement its binding capabilities. Gypsum gets added during final grinding to control how quickly the cement sets when water is added.

Different cement types serve specific construction needs:

|

Cement Type |

Primary Use |

Key Properties |

|---|---|---|

|

Type I (Ordinary Portland) |

General construction |

Standard setting time, moderate sulfate resistance |

|

Type II (Moderate) |

Structures exposed to soil/water |

Enhanced sulfate resistance, moderate heat generation |

|

Type III (High Early Strength) |

Cold-weather construction |

Rapid hardening, high early strength |

|

Type IV (Low Heat) |

Massive structures like dams |

Slow setting, minimal heat generation |

|

Type V (Sulfate Resistant) |

High-sulfate environments |

Maximum resistance to sulfate attack |

Specialty cements include white cement for decorative applications, masonry cement with pre-mixed aggregates, and oil well cement for drilling operations.

Selecting the right cement type significantly impacts the durability and performance of your project. Each type offers different setting times, strength development rates, and environmental resistance. All cement types harden through hydration—a chemical reaction with water—rather than simply drying out.

Concrete serves as the world's most widely used building material, forming the backbone of modern construction from skyscrapers to sidewalks. This composite material combines multiple ingredients to create something far stronger than its individual components, which helps explain why concrete and cement aren't the same thing.

Concrete combines four essential ingredients in precise proportions to achieve its strength:

|

Component |

Role in Concrete |

Typical Proportion |

|---|---|---|

|

Portland cement |

Binding agent |

10-15% |

|

Sand |

Fine aggregate |

25-30% |

|

Gravel/stone |

Coarse aggregate |

40-50% |

|

Water |

Activates cement |

15-20% |

Each ingredient plays a specific role in creating concrete's durability and load-bearing capacity. The exact proportions vary based on the intended application, but these components must work together to produce true concrete—cement alone simply can't provide the structural integrity needed for construction.

Pro Tip: For DIY projects, pre-mixed concrete bags from hardware stores contain all dry ingredients properly proportioned. You'll only need to add the correct amount of water according to package instructions.

The concrete-making process relies on a chemical reaction called hydration:

Once mixed with water, concrete remains workable for 1-2 hours before it begins to set. Proper mixing ensures even distribution of all components throughout the batch.

Concrete's versatility makes it suitable for numerous construction projects:

What homeowners often call a "cement slab" is actually a concrete slab. Cement alone would crack and fail immediately if used for flooring or structural applications.

Standard concrete can support between 3,000-5,000 pounds per square inch (psi) once fully cured, with specialized mixes reaching even higher strengths. This immense structural capacity explains why concrete forms the foundation of modern construction.

Concrete offers several durability advantages:

Concrete continues strengthening over time as remaining cement particles react with available moisture. Properly mixed and placed concrete can last decades or even centuries with minimal upkeep.

Many homeowners use cement and concrete as if they mean the same thing. This confusion arises from a lack of understanding of what these materials are and how they function. The differences between cement and concrete affect everything from cost to performance, so let's break down exactly how these materials compare.

The main distinction between cement and concrete comes down to what each material contains:

|

Property |

Cement |

Concrete |

|---|---|---|

|

Form |

Fine gray powder |

Solid composite material |

|

Composition |

Limestone, clay, bauxite, and iron ore |

Cement (10-15%) + water + sand + gravel/stone |

|

Role |

Binding ingredient |

Complete building material |

|

State when purchased |

Powder in bags |

Mix of dry ingredients or ready-mixed |

Cement works as the binding agent that holds concrete together. When you buy cement, you get a manufactured powder that needs water to activate. Concrete combines this cement with sand and stone to create a much stronger final product.

These materials serve completely different purposes in construction:

Cement functions as an ingredient in other materials. You rarely use it alone because it can't handle the structural demands most building projects require.

Concrete gets poured or placed to create load-bearing structures. Once it cures, concrete can support thousands of pounds per square foot, making it suitable for foundations, slabs, driveways, and structural elements.

Pro Tip: For small repairs, cement-based products might work, but any structural project needs properly mixed concrete for adequate strength and durability.

The term "cement slab" is technically wrong. Slabs are made from concrete, not pure cement. Here's the difference:

Concrete slabs combine cement with aggregates and water in specific proportions. This mixture creates a solid surface that can distribute weight evenly across its area. Pure cement would crack immediately under the same conditions.

Driveways, patios, and foundations all require concrete slabs because they need the strength that comes from cement working together with sand and stone.

Construction professionals avoid using cement by itself for several practical reasons:

These limitations explain why cement always gets combined with other materials to create concrete, mortar, or specialized mixes. Each mixture contains different proportions of cement alongside ingredients that improve specific properties like workability or water resistance.

Choosing the right material for your project means understanding what cement and concrete can actually do. Each serves different purposes, and the wrong choice can lead to expensive failures or unnecessary costs. Your project's specific requirements determine which material will work best.

Cement works for limited applications since it's primarily an ingredient rather than a standalone building material. Here's when cement-based products make sense:

Best for: Small repairs and bonding applications where structural strength isn't required.

Concrete handles the heavy-duty work that cement can't manage alone. Choose concrete for these applications:

|

Application |

Why It Works |

|---|---|

|

Foundation walls |

Supports structural loads up to 5,000+ PSI |

|

Driveways |

Withstands vehicle weight and weather |

|

Sidewalks & patios |

Provides durable walking surfaces |

|

Floor slabs |

Distributes building weight evenly |

Concrete costs between $3 and $8 per square foot for most residential applications, making it cost-effective for structural projects where strength matters.

Best for: Any load-bearing or structural application requiring long-term durability.

Consider these key factors when deciding between cement and concrete:

Load requirements - Will the surface support significant weight? Choose concrete for anything that needs to bear structural loads.

Project size - Large areas like driveways require concrete's strength and coverage. Small repairs might work with cement-based products.

Budget considerations - Concrete offers better value for structural projects, while cement works for minor fixes.

Application method - Concrete gets poured and finished, while cement-based products can be troweled or spread in thin layers.

For most home improvement projects involving floors, foundations, or outdoor surfaces, concrete is the only viable option. Make sure you choose a material that matches your project's structural demands and budget requirements.

Construction projects often fail because of persistent myths about cement and concrete. These misconceptions lead to expensive mistakes when homeowners choose the wrong material for their needs. Most people struggle to grasp how these materials relate to each other and when to use each one properly.

Concrete significantly outperforms cement in every strength category. Cement alone creates a brittle material that cracks under minimal pressure, while concrete can support massive structural loads once fully cured. Think of it like comparing flour to an actual cake—cement is just one ingredient that needs other components to become useful.

|

Property |

Cement |

Concrete |

|---|---|---|

|

Strength |

Low (brittle) |

High (3,000-5,000+ PSI) |

|

Durability |

Poor |

Excellent |

|

Crack resistance |

Minimal |

Substantial |

Never use cement as a concrete substitute. Cement lacks the structural integrity needed for construction projects and will fail immediately in load-bearing applications. Cement works as an ingredient, not a standalone building material.

People mistakenly call concrete "cement" for several reasons:

Choose your materials carefully by reading package labels and matching them to your specific project requirements. Concrete, cement, and mortar come in different formulations designed for particular applications. When in doubt, ask the hardware store staff to help you select the right material for your job.

Best for: Understanding these differences prevents structural failures and saves money on material costs.

Understanding cement versus concrete helps you make better material choices for any construction project. Cement functions as a binding ingredient—the "glue" that holds concrete together when mixed with water, sand, and aggregates. Concrete provides the structural strength needed for load-bearing applications, while cement works best for repairs or as an ingredient in mortar mixes.

This knowledge prevents expensive mistakes, whether you're planning a driveway installation or small repair work. What many people call a "cement slab" is actually a concrete slab—cement alone would crack immediately under structural weight. Similarly, using concrete for small crack repairs wastes money when a cement-based product would work better.

Make sure you choose the right material for your specific needs. Cement-based products work well for thin repairs and bonding applications. Concrete remains the only appropriate choice for foundations, slabs, driveways, patios, and any surface that needs to support significant weight. The strength difference is substantial—concrete can handle 3,000-5,000+ PSI while cement paste cracks easily under pressure.

Your project's success depends on matching the material to its intended use. Balance upfront costs with long-term durability when making your selection. Pre-mixed bags from hardware stores offer the most practical solution for small projects, with all ingredients properly proportioned—just add water according to package instructions.

Understanding the distinction between cement and concrete is crucial for any construction project to avoid costly material mistakes.

This fundamental knowledge enables you to communicate effectively with contractors, select suitable materials, and ensure that your construction projects achieve long-lasting durability and structural integrity.

GET THE ESSENCE OF RELEVANT HOME

IMPROVEMENT TOPICS IN LESS THAN 5 MINUTES

Building vs Buying a Home: Which Option Saves You More Mo...

Comparing building costs between new construction and existing homes in 2025 shows significant di...

Miscalculating concrete needs can waste up to 20% of your budget on a single project, turning wha...

Thanks for joining our homeowners’ community.

Stay tuned!

Choose the category

Choose the category